TI-004 Expansion Joint Questionaire

|

The TI-004 Spec with our expansion joint questionnaire provides the support needed for a proper design layout for our expansion joints The TI-004 Spec with our expansion joint questionnaire provides the support needed for a proper design layout for our expansion joints |

How it shouldn’t be done!

|

How you can save money

|

|

|

| Incorrect interpretation due to missing information |

Professional Design |

|

|

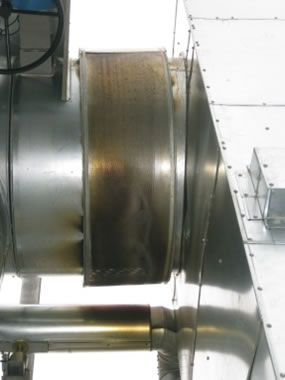

| Wrong designed belt type expansion joint without pre-formed convolution |

|

|

|

| Incorrect pre-insulation leads to premature damage to the expansion joint: Service life only three weeks |

Professional design:

Belt type expansion joint with pre-formed convolution and application-specific pre-insulation: Service life 6 years |

| |

The complete specification of all operating parameters guarantee a correct design layout.

In the video: Unknown pressure fluctuations / pulsations on a tissue expansion joint, which can lead to premature wear.

The expansion joint questionnaire TI-004 provided by the RAL Quality Assurance Association will help you with your inquiry / order and will ask all relevant operating parameters. |

| |

TI-008 Bolting connections for soft material Expansion Joints

|

The TI-007 gives you the necessary information for the correct Bolt requirements |

How it shouldn’t be done!

|

How to save money

|

|

|

Tightening torques for bolts not followed: Therefore loose screw connections!

This leads to leaks and leakage of medium. |

Observing the correct tightening torques is a prerequisite for achieving sufficient tightness. |

| |

|

TI-008 Storage, Packaging and Transportion of soft material Expansion Joints

|

For proper storage, packaging and transportation information, see TI-008. |

How it shouldn’t be done!

|

How to save money

|

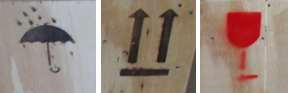

Wrong storage: Wrong storage:

Not following the proper storage instructions:

Store absolutely dry and remove shortly before installation. |

Professional Storage |

| |

Remove packaging just before installation! |

| |

|

| |

Be sure to follow notes and pictograms !! |

|

|

| Lifting of soft material expansion joints only at the designated attachment points, not at the mounting brackets! (In this example the crane eyelets were not used.) |

Using suitable load handling equipment and in compliance with the relevant safety regulations. |

| |

|

TI-009 Planning of Assemblies – soft Material Expansion Joints

|

| All the necessary information for proper planning the assembly ,see TI-009 |

How it shouldn’t be done!

|

How to save money

|

|

|

| Missing holes in the corner radius and Bent steel parts can lead to leaks. |

Holes in the corner radius achieve optimum tightness. |

|

|

Error during the assembly:

Support touches the expansion joints. Possible premature failure of the expansion joint. |

Good organization and planning of the assembly ensures a smooth assembly process and that everything is available at the right time. |

|

|

| Support touches the expansion joint |

|

| |

|

TI-010 Assembly of soft material Expansion Joints

|

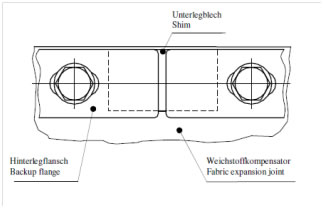

Correctly installed back up bars (diagonal or straight version is permitted) |

How it shouldn’t be done!

|

How to save money

|

|

|

Orientation of the screws, distance of the terminal strip segments and clamping bars

without an impact plate |

Proper orientation of the screws.

Correct Distance of back up bars.

Back up bars with shims underneath.

Holes and Fasteners in the proper horizontal location with each other |

|

|

| Burning of a mounting bracket – causing damage to the expansion joint |

Correctly installed back up bars (diagonal or straight version is permitted) |

|

|

| Damage caused by heat and fire |

|

|

|

Screws are installed in the wrong direction!

Back up bars without shims. |

|

| |

|

TI-011 Insulation requirements for soft material expansion joints

|

The TI-011 can protect you from damage caused by incorrect or faulty installed insulation in the expansion joint area. |

How it shouldn’t be done!

|

How to save money

|

|

|

Wrong protection against touching the expansion joint.

Insulation prevents heat dissipation. |

Touch protection with proper

Convection and heat dissipation |

|

|

| After removing the touch protection: Wrong connection for already existing insulation |

Professional execution:

New insulation connection all the way up to the flange, free convection |

|

|

Semi-insulated fabric expansion joint. This prevents convection and heat accumulation.

Additional risk of damage from sharp-edged sheets. |

|

|

|

| Heat radiation can lead to damage to the soft material expansoin joint due to incorrect installed external insulation. |

|

| |

|

TI-012 Maintenance work on soft material expansion joints as part of the plant overhaul

|

The TI-012 can help you increase the life expectance of the soft material expansion joints and protect you from premature failure. |

How it shouldn’t be done!

|

|

|

|

| Chaos during installation can lead to damage to the expansnoin joint |

|

| |

|

TI-013 Tolerances for connection parts and installation dimensions for soft material expansion joints

|

| |

How it shouldn’t be done!

|

How to save money

|

|

Lateral misalignment already incorporated by the manufacturer reduces stress and increases service life. For this, the offsets must be measured as accurately as possible. |

|

|

| Überschreitung der lateralen Exceeding the lateral mounting tolerances |

|

|

|

| |

|

TI-015 Safety management of soft material Expansion Joints

|

The TI-015 gives you important information about the safe handling of expansion joints |

How it shouldn’t be done!

|

How to save money

|

|

|

Mounting point is not secured with proper scaffolding.

As a result, there is a high risk of accidents and injury. |

Assembly site is equipped with proper scaffolding. Workers wear their personal protective equipment PPE.

This ensures a safe, quick and correct installation.

This saves time, money and nerves |

|

|

| Risk of falling! |

|

| |

|